1.Modular trailers are composed of multiple standardized modular units. Each module typically contains a fixed number of axles, tires, suspension systems and connecting mechanisms.

2.Mechanical/ hydraulic connection mechanisms are usually used between modules (mostly hydraulic connections), allowing trailers to be combined or separated quickly and safely for different transportation needs.

3.Modular trailers can increase or decrease the number of axles according to load requirements. This system allows users to customize the length and width of the trailer at will, thereby providing road transport solutions for a variety of special and standard cargo.

Modular Trailer is a special, infinitely combinable super-heavy transport vehicle designed to transport large, heavy or special-sized heavy goods. It features multiple similar modules that can be combined as needed to adapt to different load and transport requirements.

| Specification | |

|---|---|

| Rated Load Capacity(Kgs) | 25000kg/Axis×12 Axis=300,000kg |

| Max Loading Capacity(Kgs) | 37500kg/Axis×12 Axis=450,000kg |

| Net Weight Of The Trailer(Kgs) | 36,000kgs |

| Max Trailer Speed (Full Load) | 30km/Hour |

| The Distance Of Axle | |

| The Distance Of Wheel | 740/1820mm |

| Tire | 96 Suits Of 7.50R15 |

| Wheel Rim | 96 Suits Of 6.5-15rim |

| Axle | 24 Suits Of 15ton Hydraulic Steering Axle |

| Suspension | Single Point Hydraulic Suspension |

| The Thickness Of Floor | 50mm-60mm |

| Main Beam | Box Type Beam |

| Braking System | Dual-Pipes Braking System, Equipped With Pneumatic Type, Parking Brake System |

| Color And Marking | Color And Pattern According To Customer Requirements |

| Electrical System | 1. Voltage: 24v 2. Receptacle: 7 Ways (7 Wire Harness) |

| Brake Air Chamber | Double And Single Chamber |

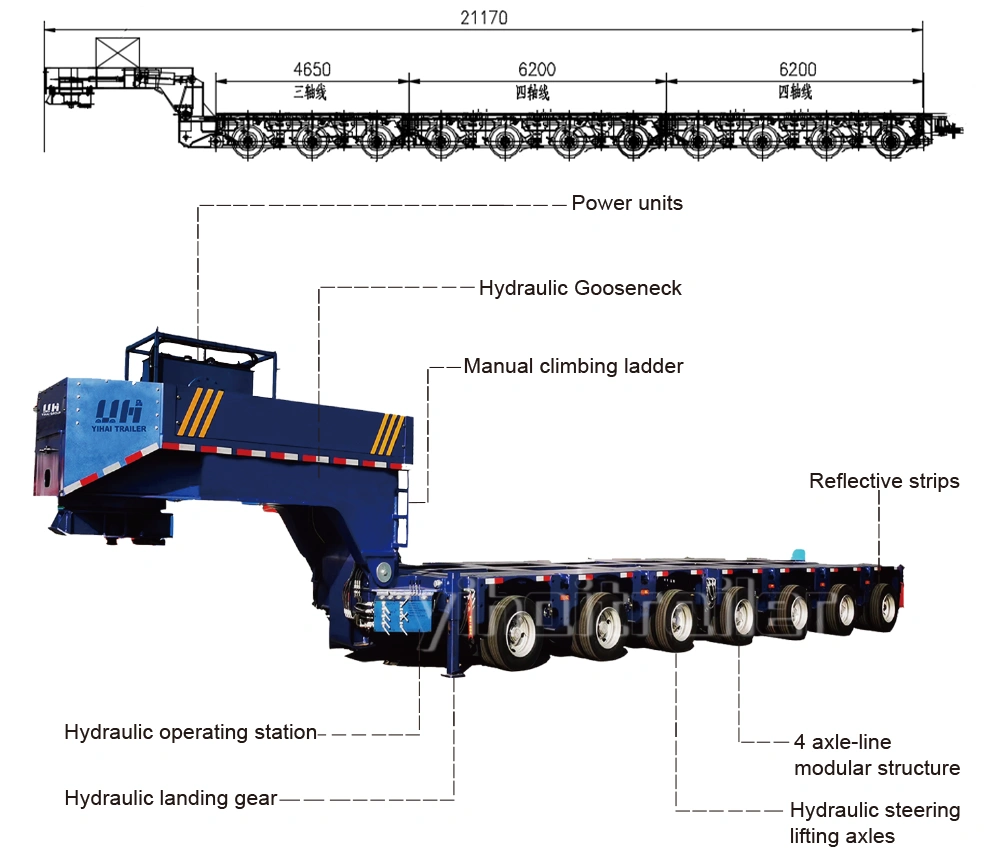

Power Units

A removable gooseneck trailer equipped with power units combines efficiency, versatility, safety, and cost-effectiveness, making it a valuable asset for transporting heavy and oversized cargo.

Manual Climbing Ladder

The manual climbing ladder on a trailer offers cost-effective access, simplicity, and user control, with a lightweight design for increased flexibility and compliance.

4 Axle-Line Modular Structure

The 4-axle-line modular structure of trailers offers enhanced load distribution, improved stability, and increased flexibility for transporting heavy or oversized loads.

Hydraulic Steering Lifting Axles

Hydraulic Steering Lifting Axles on trailers enhance maneuverability, increase load capacity, and improve fuel efficiency, providing precise control during turns and reducing tire wear and fuel consumption when running with partial loads or empty.

Some examples of items that can be transported by such a trailer include:

1.Heavy Transport: Modular trailers are widely used for transporting heavy and oversized goods, such as large machinery, generators, transformers, and other industrial equipment.

2.Wind Power Industry: In the wind power industry, the enormous components of wind turbines, such as generators and blades, need to be transported to wind farms.

3.Maritime and Shipbuilding: In shipbuilding, large ship components, such as hulls and keels, need to be transported.

Due to its modular structure, the trailer’s load configuration is more flexible. Trailers can be designed to the length, width and load capacity, allowing them to carry cargo of all shapes and sizes. This means that the same trailer can be suitable for many different transport tasks.

FAQ of Modular Trailer

Yes, the design of the modular trailer allows users to adjust its length and width by adding or subtracting modules to meet different transportation needs.

Suitable for various oversized, overweight or irregular-sized goods, such as wind turbine blades, large bridge components, chemical plant reactors, factory equipment, etc.

This 7 line-axles modular trailer has a carrying capacity of 175 tons. In fact, the specific carrying capacity of a modular trailer depends on the configuration requirements, and its carrying capacity ranges from dozens of tons to hundreds or even thousands of tons.